Lockup latches or flops are used in scan chains to fix hold time issues and ensure correct timing during shift operations. These latches do not interfere with the non-scan functional behavior of a design. However, if not managed properly during functional ECO flow, they can inadvertently affect the outcome of an ECO, particularly in metal-only ECO scenarios. An optimal ECO requires special handling of lockup latches to avoid introducing redundant or unnecessary logic.

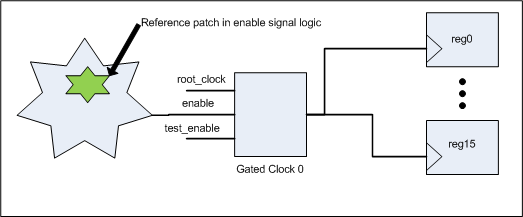

In this use case, the RTL changes involve updates to a gated clock enable signal logic. Figure 1 illustrates the reference design where modifications have been made to the gated clock enable logic. When implementing the design, the ECO process should apply a corresponding patch to this logic.

Figure 1 Reference design has gated clock enable signal logic modification

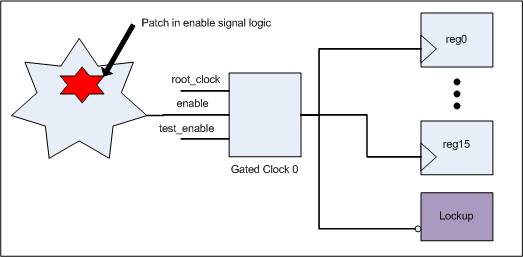

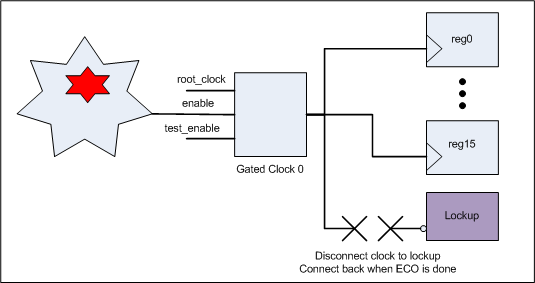

However, in the implementation design, the gated clock driving the logic also drives additional lockup latches that are not present in the reference design, as shown in Figure 2.

Figure 2 Implementation design drives extra lockup latches

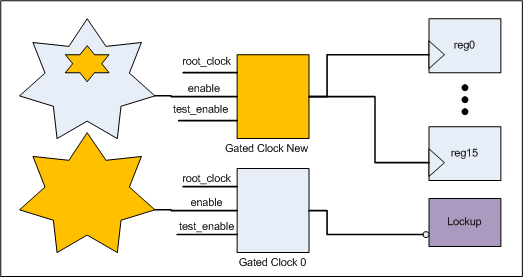

Without special handling of these lockup latches during the ECO process, redundant logic, such as new gated clock cells and duplicated enable signal logic, can be introduced. Automatic ECO tools, GOF ECO, or Conformal ECO will generate the same issue. In Figure 3, the redundant logic is shown in orange.

Figure 3 Redundant ECO logic created for the lockup latches

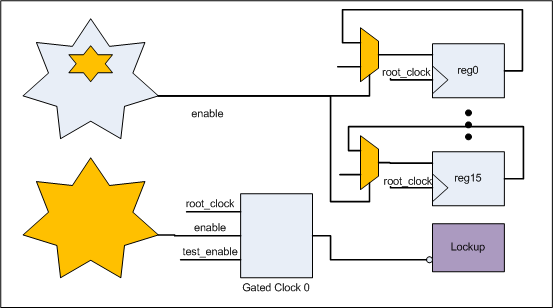

In this particular metal-only ECO case, due to the unavailability of spare gated clock cells, the introduction of 16 multiplexers (MUXs) would be required to handle the clock conversion. This significantly increases resource usage and leads to a lack of spare gates necessary to complete the job, as shown in Figure 4.

Figure 4 Gated clock converted in metal only ECO

The optimal solution is to temporarily disconnect the lockup latches before applying the automatic ECO. After the ECO process completes, the lockup latches are reconnected. This method prevents the creation of unnecessary logic, reduces resource consumption, and ensures a clean and efficient ECO outcome.

Figure 5 Solution to the lockup latches

# GofCall ECO script, run_metal_only_lockup_example.pl # Lockup latches are treated specially use strict; undo_eco; # Discard previous ECO operations # Setup ECO name, had better be unique to avoid naming confliction setup_eco("eco_example"); read_library("art.90nm.lib"); # Read in standard library read_design("-ref", "reference.gv"); # Read in the Reference Netlist read_design("-imp", "implementation.gv"); # Read in the implementation Netlist Which is under ECO # Disconnect lockup latches' clock pins before automatic fix set_top("state_control"); # Set to module 'state_control' my @locks = get_cells("lockup*"); # Get all cells with 'lockup' string my $oldcons = {}; foreach my $lock (@locks){ my @drv = get_driver("$lock/CK", "-nonbuf"); $oldcons->{$lock} = \@drv; change_pin("$lock/CK", ""); } fix_design(); # Connect back lockup latches' clock pins set_top("state_control"); # Set to module 'state_control' foreach my $lock (@locks){ my ($inst, $pin, $dtype) = @{$oldcons->{$lock}}; change_pin("$lock/CK", "$inst/$pin"); } set_top("topmod"); # Set to the most top module # Now we need to map all new added ECO gates to spare type instances read_def("topmod.def"); # Read Design Exchange Format file, optional. # Specify spare cell pattern, when 'map_spare_cells' is done, # a new updated spare list file will be written out. # The updated spare list file has default name 'spare_cells_script_name.list'. # Click 'get_spare_cell' below for more usage detail get_spare_cells("*/*_SPARE*"); # Comment the above line and use the following line to use spare list file # if the spare list file has been generated already and gone through other ECOs # get_spare_cells("-file", "spare_list_file.txt"); map_spare_cells(); report_eco(); # ECO report write_verilog("eco_verilog.v"); # Write out ECO result in Verilog write_soce("eco_soce.tcl"); # Write out TCL script for SOC Encounter exit; # Exit when the ECO is done, comment it out to go to interactive mode when 'GOF >' appears

To achieve the best ECO results, combining Automatic and Manual ECO modes is the ideal approach. This is especially crucial in Metal-Only ECOs, where resources are highly constrained.